Advanced NDT

Ultrasound Inspection

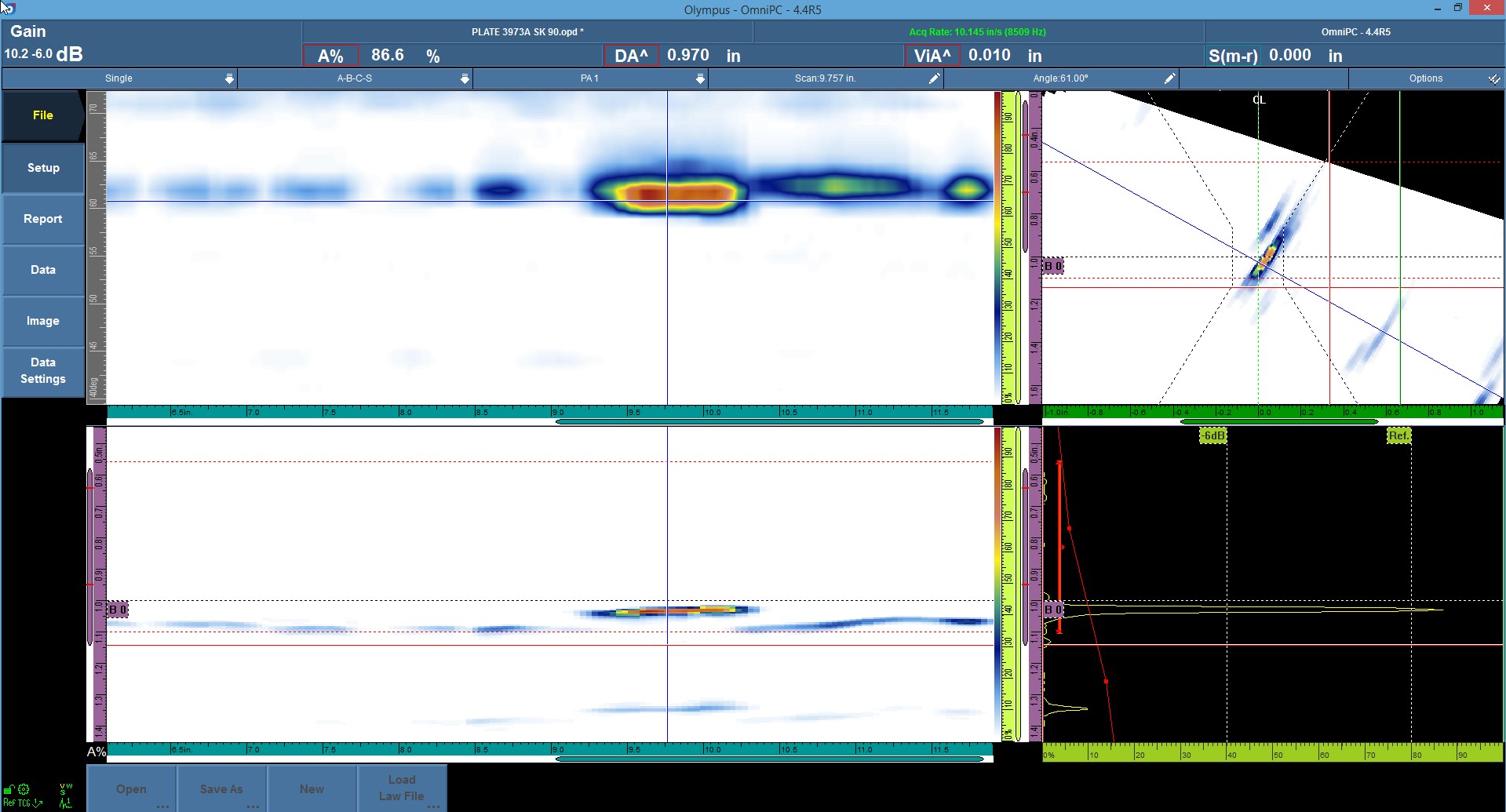

Phased Array Ultrasonic Testing (PA UT) is an advanced science, using high speed electronics and composite multi-element array probes to produce ultrasonic waves. The UT waves are combined, producing highly accurate images that identify geometry, anomalies, and flaws.

Overview

Fast and Accurate – Mechanized scanning of parts with Phased Array UT technology provides 10 to 100 times faster data acquisition of large areas when compared to conventional UT methods.

Industry Recognized – Phased Array technology is recognized for use by almost all governing codes, most notably ASME, which is often a reference code book for most critical and pressure vessel applications.

Quick Archival – Phased array technology allows for quick archival and retrieval of data, a typical code requirement.

Cost Savings – Substantial on-site cost savings are achieved from speed but even more so from the opportunity to work side-by-side with all on-site personnel. Using UT eliminates the requirement of establishing worker “exclusion zones” associated with X-ray imaging, eliminating any potential for health physics issues or late-night, off-hour, inspections.

Ease of Access – With Phased Array technology, access to tight spaces is possible using miniaturized phased-array probes and semi-automated scanners.

Phased Array Experience

Baker Testing uses Phased Array in a wide variety of applications. Teams of technicians and UT Level III personnel are available to deploy for small custom jobs or larger scale, high volume part applications.

Bridge Inspection

Read document

Encoded Phased Array Bridge Pin Inspection (.pdf)

Marine Vessels and Structures

Traditional experience in steel and metal materials and expertise in the newer Advanced Carbon Composite materials used in the manufacture of Racing Tri-Marans and Luxury Yachts

Automotive, Aerospace, and Transportation

Special Composites inspection and Bond applications

Power Generation Field Services

The Nuclear Power industry was one of the first to adopt and embrace the use of Phased Array technology for pressure vessel weld inspection. Now, traditional Oil and Gas fired plants are calling upon this technology for Critical Welds in Steam Piping from Headers to feeder tubes ultimately expanding usable life cycles of Boilers.

Pipe Installation and Weld Inspection

- ASME Code based weld inspection of pressure piping

- UT in lieu of X-ray for cost benefits and advantages

Building and Land Based Infrastructure Development and Maintenance

AWS code based weld inspection requirements are now being augmented with Phased Array under Annex K for tremendous cost savings.

Qualified NDT Technicians

- Baker Testing has extensive experience using Phased Array technology

- In-depth knowledge has been gained by solving hundreds of different applications

- Our tool box is full with probes, wedges, and scanners to solve your application

- We use the latest and most widely accepted Phased Array instrumentation & equipment

Certification & Education

- ASNT UT Level III & Level II technicians

- Certified training on methods, procedures, and equipment to provide quality inspection

- On-staff quality assurance personnel

- Over 40 years of ultrasound experience