Casting, Forgings and

Machine Rolled Products

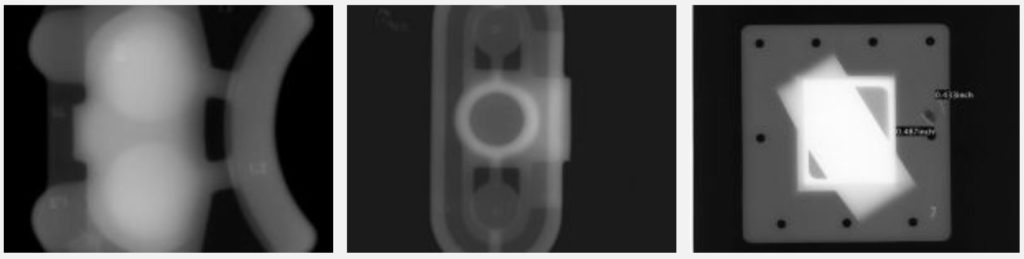

Baker Testing provides non-destructive testing (NDT) and inspection of cast, forged, rolled and machined products at various stages of manufacture to assure compliance with codes, contracts, and specifications.

NDT Detection of Casting flaws

Casting inspection requires surface and sub-surface testing. We use two complementary methods during inspection to detect various flaws.

| Gas holes | Cracks |

| Porosity | Cold shuts |

| Sand | Hot tears |

| Dross | Unfused chaplets |

| Cavities | Chills |

| Foreign material | Blow holes |

| Shrinkage Inclusions | Shrinkage tears |

Forging and Rolled Materials

Forging and rolled material flaws that are detectable by NDT and destructive testing include forging bursts, cracks, laps, folds, inclusions, flakes, seams, stringers, porosity, tears and flakes.

NDT Techniques for Manufacturing

Qualified technicians apply many NDT test methods – at our labs or in the field – to detect and evaluate both surface and internal discontinuities to identify potential flaws.

- Digital and film Radiography (RT)

- Fluorescent and color contrast Liquid Penetrant (FPI, PT) Type I and Type II, Methods A and C

- Wet fluorescent and dry powder Magnetic Particle (MPI, MT) with AC or DC applications

- Ultrasonic thickness measurement and flaw detection (UT) various applications

- Visual Inspection (VT) to customer specifications

Prior to machining, discontinuities like those noted above can be identified, evaluated and culled from production – thus saving cost and time.

After machining and final surface conditioning, testing by non-destructive methods is often required to identify otherwise invisible flaws and discontinuities.

Experienced Technicians

Baker Testing provides cost effective, quality control services for customers in a variety of industries. We have over 40 years of non-destructive testing experience.

- Medical Instrument

- Surgical Implant Production

- Automotive, Rail, Aviation, and Transportation Equipment

- Construction Equipment Producers and Repair Facilities

- Firearms Foundry and Manufacturing

- Construction

- Machining, Manufacturing, and Fabrication