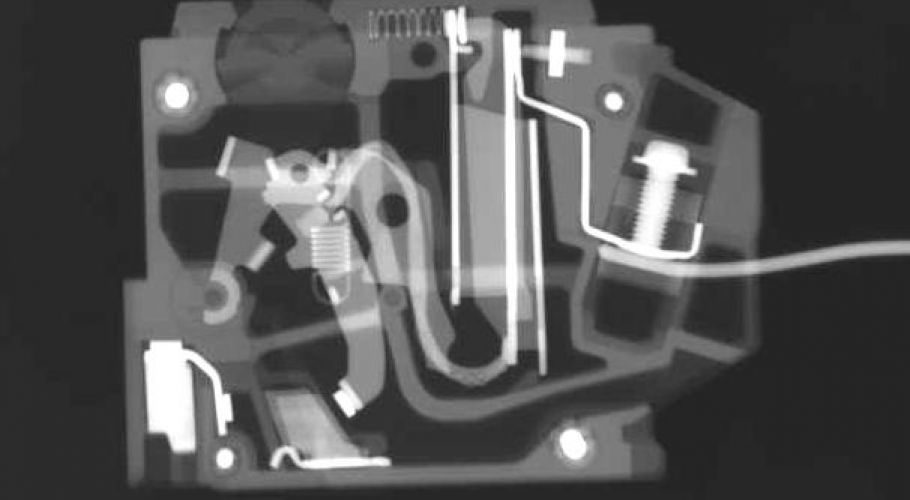

Non-destructive testing (NDT) of electronic components such as electronic cables, switches, laptops, and circuit boards provides improved quality during manufacturing and assembly.

Additionally, electronics engineers and failure analysis scientists work with Baker Testing to x-ray both failed and exemplar units of many different electronic components to image for comparison. Side-by-side analysis helps identify differences and possible causes of failure. Analysis is also a tool used for reverse engineering.

NDT Techniques for Electronic Components

Baker Testing uses several NDT methods to inspect electronics with the most common being digital x-ray, liquid penetrant, and magnetic particle.

Radiography is used to identify defects in assemblies, location of components, air pockets, and solder problems.

Liquid Penetrant and Magnetic Particle are used to detect surface cracks and laminations.

Experienced Technicians

Baker Testing provides cost effective, quality control services for customers in a variety of industries. We have over 40 years of non-destructive testing experience.